vacuum tube, tube for vacuum bagging, vacuum hose for rtm, vacuum hose for resin infusion, autoclave, composite lamination

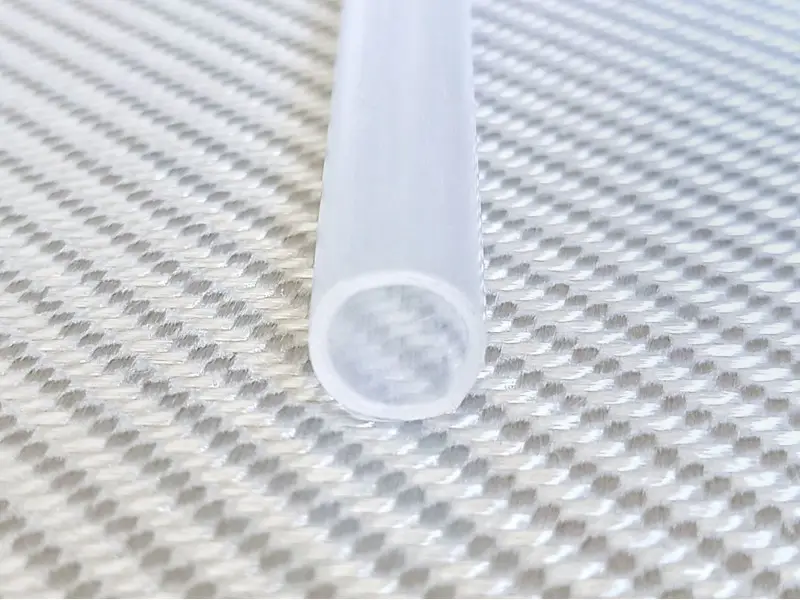

Low-density polyethylene (LDPE) pipe used in resin infusion and vacuum bagging processes, particularly in the manufacturing of composite materials. LDPE tubes are used to facilitate and control the flow and distribution of air or resin throughout the mold, ensuring that the composite material is fully impregnated and free of voids. LDPE pipes are widely incorporated into composite manufacturing processes across multiple industries, including aerospace, UAVs, automotive and marine, where the quality and reliability of composite materials are essential.

Technical characteristics

Material type: Polyethylene

External diameter: 10 mm

Internal diameter: 8 mm

Pipe thickness: 1 mm

Max temp: 90 oC

Material type: Polyethylene

External diameter: 10 mm

Internal diameter: 8 mm

Pipe thickness: 1 mm

Max temp: 90 oC

Features & Benefits

• It is lightweight and easy to handle, cut, and install, which can reduce labor costs and improve efficiency during the setup of the infusion process.

• Highly flexible and easy to route through complex molds and around tight corners, ensuring consistent resin flow and precise control over the resin infusion process with optimal mechanical properties.

• It prevents air and moisture from contaminating the resin, offering a high quality and void-free laminate.

• Resistant to exotherm temperatures involved during resin infusion, maintaining its structural integrity throughout the process, without collapsing.

• Compatible to a wide range of chemicals, including resins used in infusion processes, such as epoxy, polyester, and vinyl ester, making it a versatile choice for different composite manufacturing applications.

• It is lightweight and easy to handle, cut, and install, which can reduce labor costs and improve efficiency during the setup of the infusion process.

• Highly flexible and easy to route through complex molds and around tight corners, ensuring consistent resin flow and precise control over the resin infusion process with optimal mechanical properties.

• It prevents air and moisture from contaminating the resin, offering a high quality and void-free laminate.

• Resistant to exotherm temperatures involved during resin infusion, maintaining its structural integrity throughout the process, without collapsing.

• Compatible to a wide range of chemicals, including resins used in infusion processes, such as epoxy, polyester, and vinyl ester, making it a versatile choice for different composite manufacturing applications.