enka channel, polyester enka channel for vacuum bagging, enka channel for infusion, autoclave, composite lamination

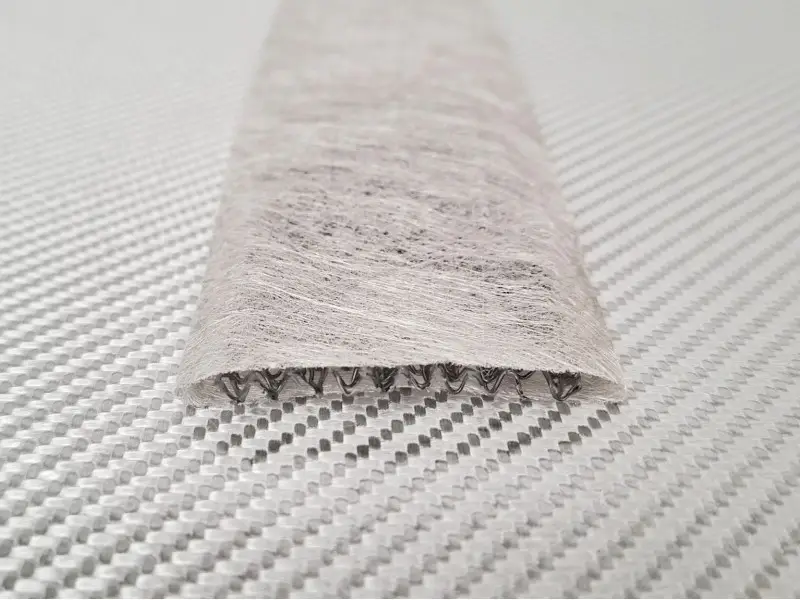

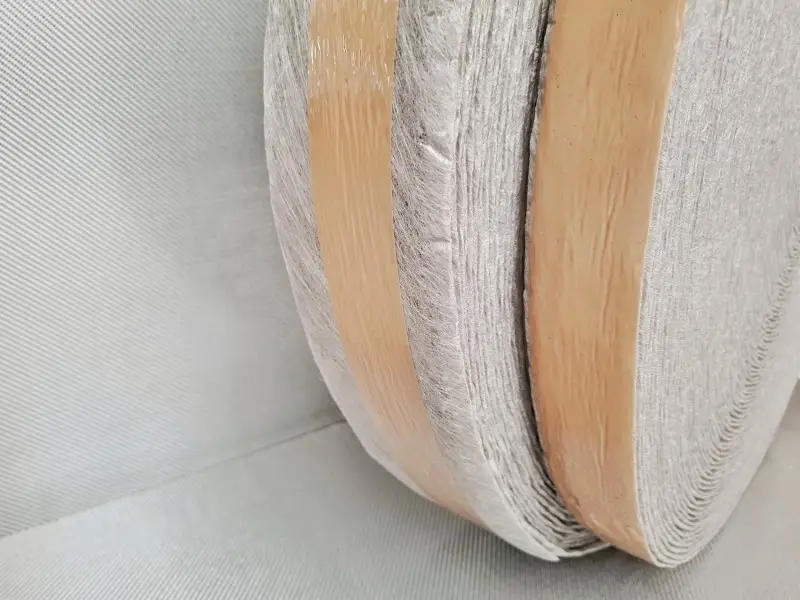

Enka channel consists of a three-dimensional spacer enclosed in a thermally bonded nonwoven polyester channel. The spacer is made of black polymeric monofilaments and features a flexible zig-zag design. Enka channel is used in infusion processes in order to facilitate fast and consistent resin distribution into the composite part. It is versatile, easy to cut to the required size and easy to secure it on the mold, with spray adhesive. Its unique structure ensures high resin flow, making the infusion more efficient and reducing processing times. Also, it leaves a clean finish with no imprints (print-through) on the laminate when removed.

Technical characteristics

Material types: Nonwoven polyester (channel) & polymeric monofilaments (spacer)

Roll length: 100 meters

Width: 50 mm

Thickness: 4 mm

Areal weight: 533 g / m2

Linear weight: 54 g / lm

Max temp: 80 oC

Features & benefits

Flexible structure

Easy to cut and secure it on the mold

Fast and consistent flow

Minimal resin uptake

Low exotherm heat

No imprints on the laminate

Easy to cut and secure it on the mold

Fast and consistent flow

Minimal resin uptake

Low exotherm heat

No imprints on the laminate