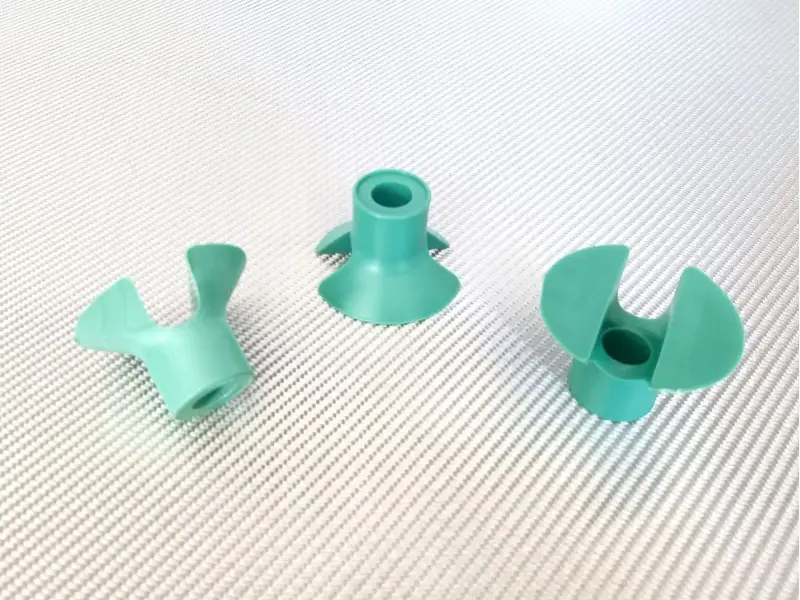

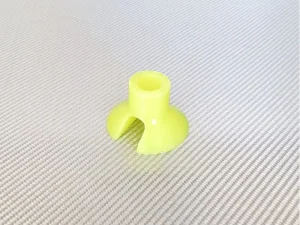

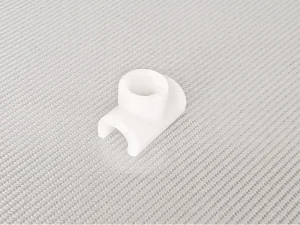

resin infusion plug, infusion connector for vacuum bagging, infusion plug for rtm, plug for resin infusion, autoclave, composite lamination

Resin infusion plugs are an essential component for resin infusion and vacuum bagging processes. They are used to seal off vacuum bag or mold areas, preventing resin escape and maintaining optimal vacuum pressure. Made from polypropylene, they can handle the high pressures of vacuum-assisted processes. Their rounded edges protect vacuum bags from tearing, which enhances resin flow, composite impregnation, and final product quality.

Technical characteristics

Fits to tube with a 15 mm external diameter.

Material type: Polypropylene

Maximum use temperature: 120°C (248°F)

Material type: Polypropylene

Maximum use temperature: 120°C (248°F)

Features & Benefits

• Made from a highly durable polypropylene that can endure the high pressures in vacuum-assisted processes.

• Provides a tight seal for the tubes, ensuring no resin leakage and optimal vacuum pressure maintenance.

• Designed with rounded edges to prevent damage or tearing of vacuum bags.

• Ensures consistent resin distribution and reduces the risk of defects leading to better composite impregnation and maintaining a leak-free environment.

• Minimizes waste and rework by ensuring a reliable infusion process, leading to higher-quality products.

• Compatible with commonly used tubing sizes, making them adaptable for various infusion setups.

• Utilized in marine, wind power, aerospace and UAV industries, where high performance is required.

• Made from a highly durable polypropylene that can endure the high pressures in vacuum-assisted processes.

• Provides a tight seal for the tubes, ensuring no resin leakage and optimal vacuum pressure maintenance.

• Designed with rounded edges to prevent damage or tearing of vacuum bags.

• Ensures consistent resin distribution and reduces the risk of defects leading to better composite impregnation and maintaining a leak-free environment.

• Minimizes waste and rework by ensuring a reliable infusion process, leading to higher-quality products.

• Compatible with commonly used tubing sizes, making them adaptable for various infusion setups.

• Utilized in marine, wind power, aerospace and UAV industries, where high performance is required.