perforated film, perforated film for vacuum bagging, perforated film for prepreg, perforated film for infusion, autoclave, composite lamination

Perforated release film is used in vacuum bagging, resin infusion, and autoclave composite processes. It features small, evenly spaced holes that allow excess resin and trapped air to escape, preventing pooling and ensuring even distribution which enhances the composite's quality and consistency. It is typically placed above the peel ply, followed by the breather fabric, and then the vacuum bag. The breather fabric facilitates air and resin flow, while the perforation ensures excess resin and air escape and help maintain even vacuum pressure.

Technical Characteristics

Technical Characteristics

Width: 1.50 meter

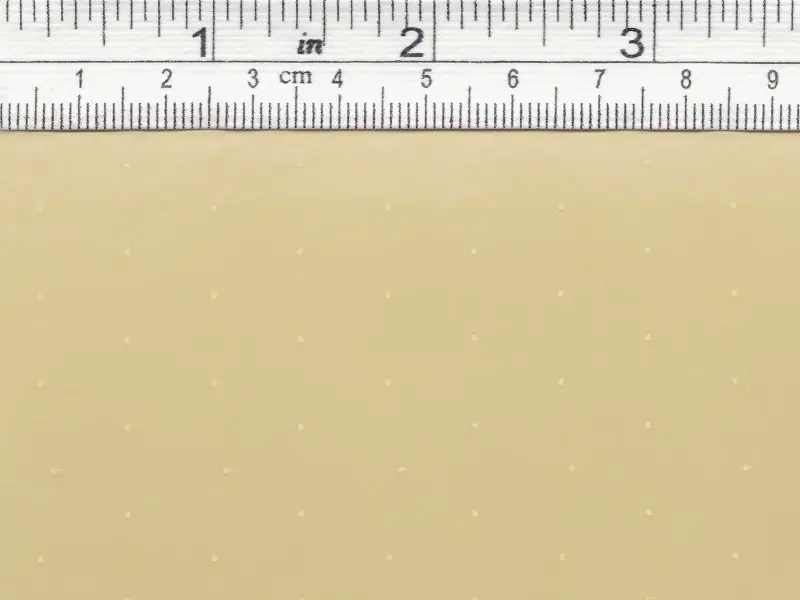

Thickness: 30 μ

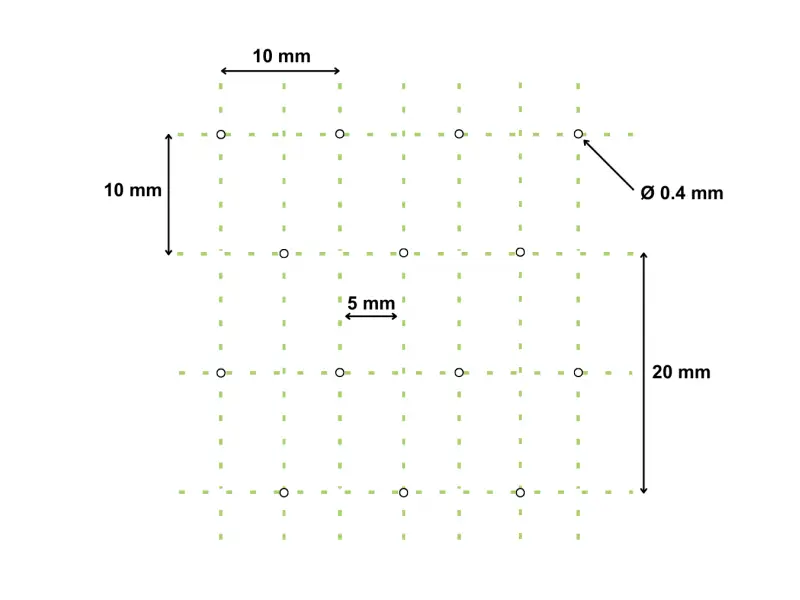

Density of perforation (step): Every 10 mm

Average size of perforation: 0.4 mm

Max temp: 170 oC (338 oF)

Thickness: 30 μ

Density of perforation (step): Every 10 mm

Average size of perforation: 0.4 mm

Max temp: 170 oC (338 oF)

More suitable for use with pre-impregnated

Features & Benefits

• Designed to facilitate the removal of excess resin and trapped air, which improves the consistency and quality of the composite.

• Acts as a protective layer between the composite laminate and the vacuum bag.

• Works effectively with other consumables like peel ply, breather fabric, and vacuum bags.

• Helps in the effective removal of trapped air and volatiles, leading to better consolidation and curing.

• Leaves a clean, resin-free surface when used with peel ply, which is ideal for bonding.

• Ensures uniform vacuum pressure across the composite, which contributes to optimal curing and mechanical properties.

• Essential for high-quality results, perforated release film is widely used in marine, aerospace, UAV, and automotive industries.

• Designed to facilitate the removal of excess resin and trapped air, which improves the consistency and quality of the composite.

• Acts as a protective layer between the composite laminate and the vacuum bag.

• Works effectively with other consumables like peel ply, breather fabric, and vacuum bags.

• Helps in the effective removal of trapped air and volatiles, leading to better consolidation and curing.

• Leaves a clean, resin-free surface when used with peel ply, which is ideal for bonding.

• Ensures uniform vacuum pressure across the composite, which contributes to optimal curing and mechanical properties.

• Essential for high-quality results, perforated release film is widely used in marine, aerospace, UAV, and automotive industries.