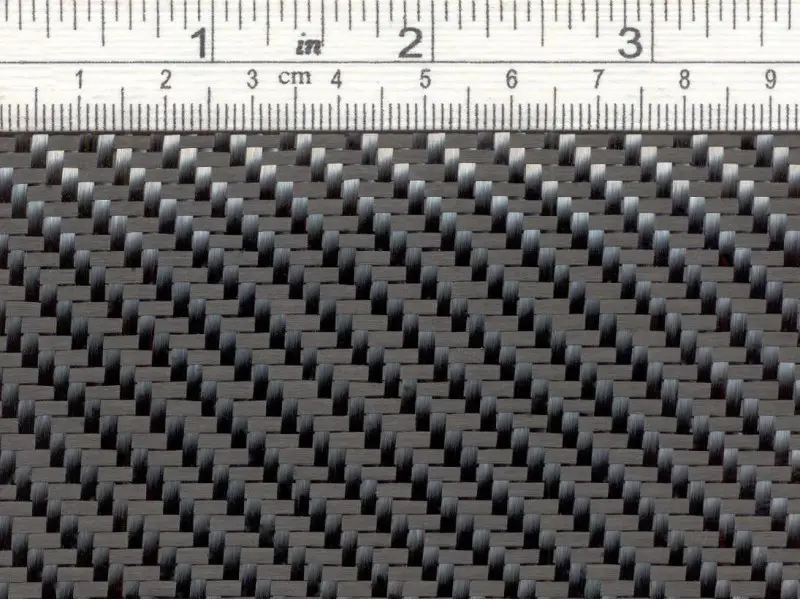

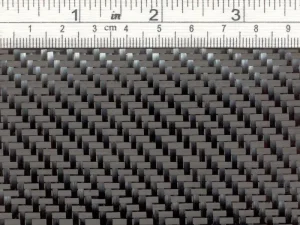

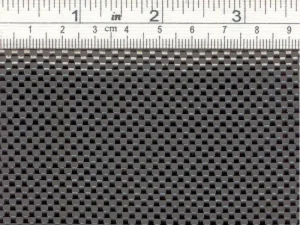

prepreg carbon fiber, carbon prepreg, carbon fibre 3k tr30s, carbon fabric twill 160 g

Width: 1.00 meter

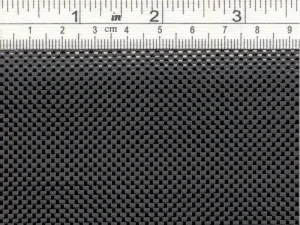

Warp: 3K TR30S carbon fiber, 50%, 5.25 ends (threads) / cm

Weft: 3K TR30S carbon fiber, 50%, 5.25 ends / cm

Epoxy content: 42 %

Gel time at 125 oC: 11 min

Volatile content: < 1 %

Fibermax general purpose prepregs are based on a 80 to 150 oC (176 – 302 oF) curing toughened epoxy matrix, suited for both autoclave and press molding applications. A standard autoclave curing cycle is: Draw vacuum (0.6 – 0.7 bar) and apply positive pressure. Then start heating – typically 2-5 oC / min (3.5 – 9 oF) – till 120 oC (248 oF) and then hold this temperature for 1 hour. Turn off the temperature and cool under pressure to 60 oC (140 oF). When fully cooled open the bag and extract the piece.

4 – 6 weeks at room temperature

Allow prepreg roll to reach room temperature before opening plastic bag to prevent condensation.

1 hour at 130 oC (266 oF): 130 – 140 oC (266 – 284 oF)

10 min at 150 oC (302 oF): 130 – 150 oC (266 – 302 oF)

Flexural strength (Mpa): 850

Flexural modulus (Gpa): 54

Tensile strength (MPa): 550

Tensile modulus (GPa): 60

ILSS – Short Beam Shear (Mpa): 67

Tg (DSC) 20 oC / min: 128 oC