Showing 1–16 of 21 results

Showing 1–16 of 21 results

Product Description & Applications

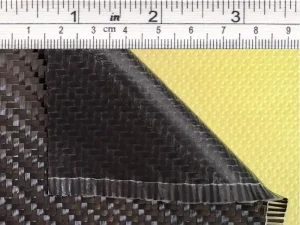

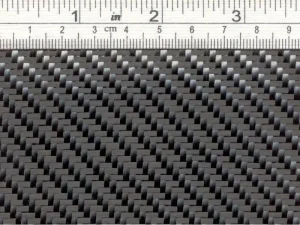

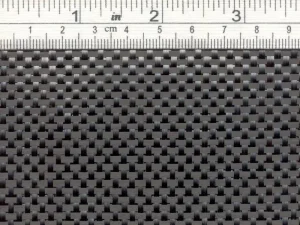

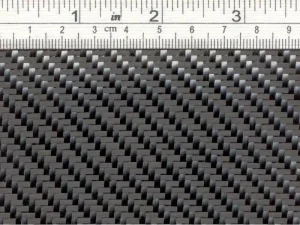

Carbon fiber prepregs are a combination of carbon fiber and resin, pre-impregnated for easy processing and outstanding performance. The carbon fibers provide exceptional tensile strength, while the resin matrix ensures the material is durable and easy to mold into complex shapes. Prepreg materials are ideal for industries that require high precision and advanced mechanical properties, such as aerospace, automotive, and industrial manufacturing.

Applications

Our carbon fiber prepregs are used in a wide range of applications where high strength, low weight, and excellent durability are required. Some common uses include:

- Aerospace: Prepreg carbon fiber is used for manufacturing lightweight and strong aerospace components, including fuselages, wings, and structural reinforcements. The superior strength-to-weight ratio helps increase fuel efficiency and performance.

- Automotive: In the automotive industry, carbon fiber prepregs are used for body panels, chassis components, and structural reinforcements. The reduced weight and improved strength help enhance vehicle performance and safety.

- Industrial Manufacturing: Carbon fiber prepregs are used in machinery parts, structural components, and tools, where high strength and resistance to wear and corrosion are required. Prepregs offer a cost-effective way to produce complex, high-performance parts.

- Sports Equipment: Prepreg carbon fiber is used in the production of high-performance sports equipment, including bicycles, tennis rackets, golf clubs, and more, providing athletes with lightweight, durable, and strong equipment.

Technical Specifications

Our carbon fiber prepregs are available in a variety of specifications to suit the needs of different industries and applications. Below are the key features of our prepreg materials:

- Resin Type: We offer prepregs with different resin systems, including epoxy, phenolic, and polyester, to meet various performance and processing requirements.

- Fiber Types: Our prepregs are made with high-quality carbon fibers, including T300, T700, and other specialized fibers, offering varying levels of strength and stiffness.

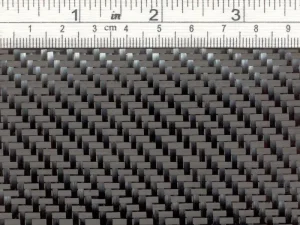

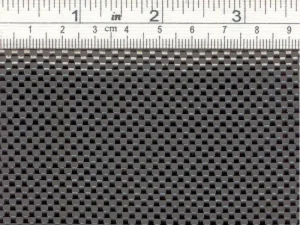

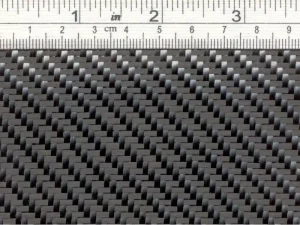

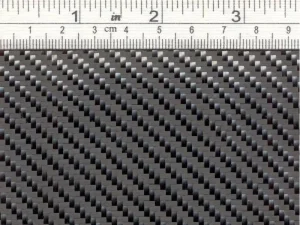

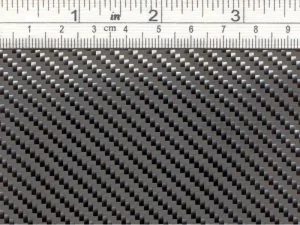

- Fiber Orientation: Prepregs can be customized with specific fiber orientations such as unidirectional, bidirectional, or woven fabrics, providing different mechanical properties depending on your application.

- Thickness: Prepreg materials come in various thicknesses, from 0.5mm to 5mm, allowing for customization based on project requirements.

- Temperature Resistance: Our carbon fiber prepregs are engineered to withstand temperatures up to 200°C to 300°C, making them suitable for both high-performance and extreme environment applications.

Customization Options

We offer a range of customizable prepreg options to suit the specific needs of your project. Whether you need specialized resin systems, custom fiber orientations, or tailored thicknesses, we can provide a solution that delivers optimal performance for your application.

Frequently Asked Questions

What is carbon fiber prepreg and how is it used?

Carbon fiber prepreg is a composite material made by impregnating carbon fiber with a resin system. The prepreg is ready for molding and curing, allowing for precise control over the material’s properties. It is typically used in industries where high strength, low weight, and resistance to extreme conditions are essential.

How do I choose the right carbon fiber prepreg for my project?

The choice of carbon fiber prepreg depends on factors such as the desired strength, weight, temperature resistance, and the resin type. You can select different resin systems and fiber orientations to meet the specific needs of your application. Our team is here to help guide you through the selection process based on your project requirements.

Can carbon fiber prepregs be customized for specific applications?

Yes, we offer fully customizable carbon fiber prepregs, including different resin systems, fiber types (e.g., T300, T700), fiber orientations (unidirectional, woven), and thicknesses. Customization ensures that the prepreg material meets your specific requirements for performance and design.

What industries use carbon fiber prepregs?

Carbon fiber prepregs are used in a variety of industries, including aerospace, automotive, industrial manufacturing, and sports equipment. They are ideal for producing lightweight, high-strength components that require superior performance and durability.