Showing 1–16 of 22 results

Showing 1–16 of 22 results

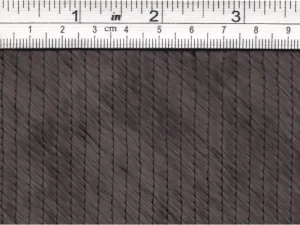

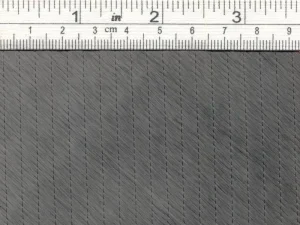

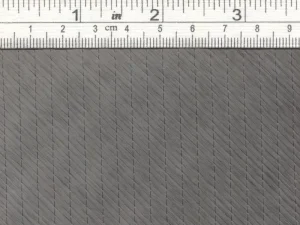

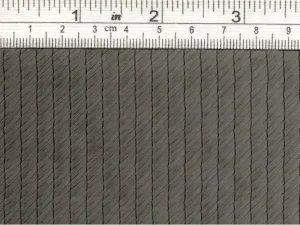

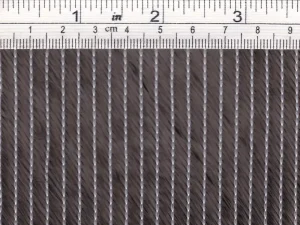

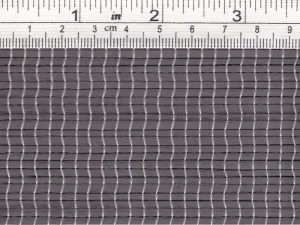

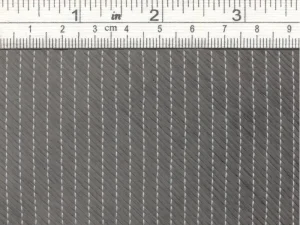

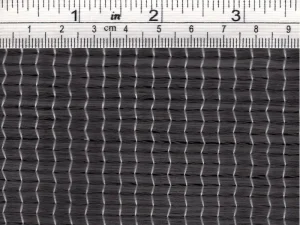

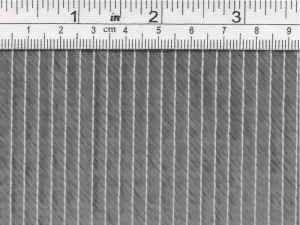

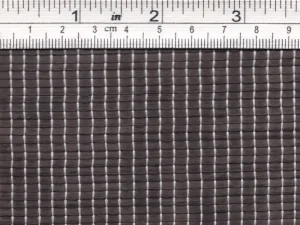

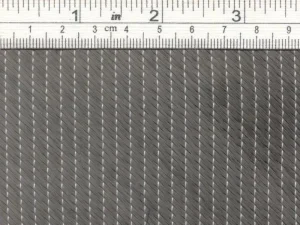

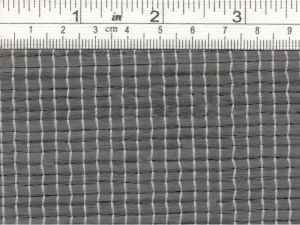

Multiaxial Carbon Fiber Fabric

Multiaxial carbon fiber fabric is a high-performance composite material constructed by layering unidirectional carbon fiber tows in multiple orientations (0°, 90°, ±45°, or custom angles) and bonding them with a lightweight stitching or resin matrix. This advanced structure delivers balanced strength across all axes, eliminating weak points found in traditional woven fabrics. It is widely used in load-bearing applications requiring superior mechanical performance, efficiency, and design flexibility.

Core Advantages

- Multi-Directional Strength: Optimized fiber orientation (e.g., 0°/90°/±45°) provides uniform tensile, compressive, and shear strength, ideal for complex load scenarios.

- High Fiber Volume Fraction: Up to 65% fiber content (vs. 45–55% in woven fabrics) maximizes structural efficiency and reduces resin waste.

- Rapid Layup & Cost Savings: Pre-aligned layers eliminate cutting/angling during production, reducing labor time by 30–50% for large components.

- Design Flexibility: Customizable layer configurations (2-axis, 3-axis, 4-axis, or 6-axis) and areal weights to match specific load requirements.

- Low Void Content: Tight fiber packing and minimal crimping ensure superior resin impregnation, enhancing composite durability and fatigue resistance.

Product Specifications

- Fiber Type: T300–T1100 PAN-based carbon fiber (1K–24K tow); standard modulus (SM) or high modulus (HM) options.

- Axial Configuration: Biaxial (0°/90°, ±45°), Triaxial (0°/±45°), Quadaxial (0°/90°/±45°), or custom angles (e.g., ±30°, ±60°).

- Areal Weight: 150–1,200 g/m² (standard); custom weights available for bulk orders.

- Thickness: 0.2mm–1.5mm (single ply); multi-ply lamination for higher thickness.

- Stitching: Polyester or aramid thread (10–20 stitches/cm) for layer stabilization; optional resin pre-impregnation (prepreg) for out-of-autoclave processes.

- Width: 1m–2.5m (standard rolls); slit-to-width options available.

Key Applications

- Aerospace: Aircraft wings, fuselages, and rotor blades (reduces weight by 20–30% vs. metallic structures).

- Wind Energy: Wind turbine blade spar caps and root reinforcements (improves fatigue life by 40%+).

- Automotive: Racing car monocoques, EV battery enclosures, and lightweight chassis components.

- Marine: Boat hulls, masts, and superstructures (enhances impact resistance and reduces fuel consumption).

- Industrial: Pressure vessels, storage tanks, and structural retrofitting (bridges, buildings) for high-load bearing.

Wholesale & Retail Solutions

Bulk Wholesale: Minimum 500 meters; custom axial configurations, areal weights, and widths. Volume discounts for 1,000m+ orders; prepreg options available with epoxy, phenolic, or BMI resins.

Retail & Prototyping: Standard rolls (50m–100m) in 2-axis (0°/90°) and 4-axis (0°/90°/±45°) configurations. Sample kits (1m²) with multi-weight options for material testing.

Quality Assurance: ISO 9001/AS9100 certified production, full traceability (fiber lot-to-finished fabric), and test reports (tensile strength, fiber orientation, areal weight).